The ProjectI was asked to build the local content for the North American premiere of the exhibit "Hockey: Faster than Ever" - hosted at the Pacific Science Center to coincide with the Kraken NHL team opening season.

Our goal was to create an environment that showcased graphics content in an engaging way. I wanted to incorporate elements of a hockey arena while designing for maintainability. |

Build Requirements

|

Our Solutions

I worked closely with the full-time technician on staff to ensure the build incorporated the electronics and maintainability from the start. I took the technology needs into account and developed an access system that was maintainable for the tech onsite, but not so robust that it greatly outlived the 3 month traveling exhibit, adding time and expense to the process.

|

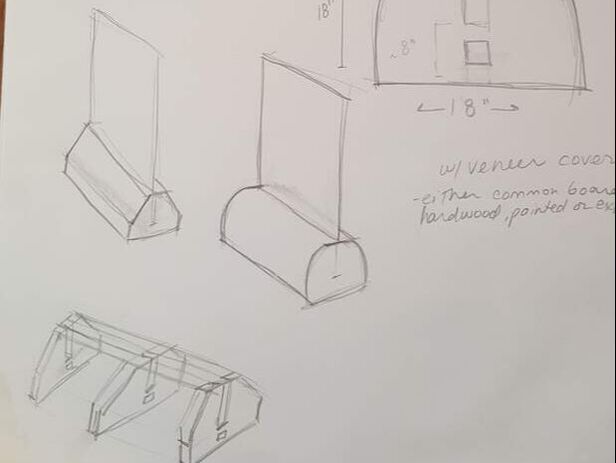

The main draw of the exhibit was illuminated acrylic panels featuring local content on graphics. The original concept had full-sheet acrylic panels sitting in low bases and rigged to the ceiling for support.

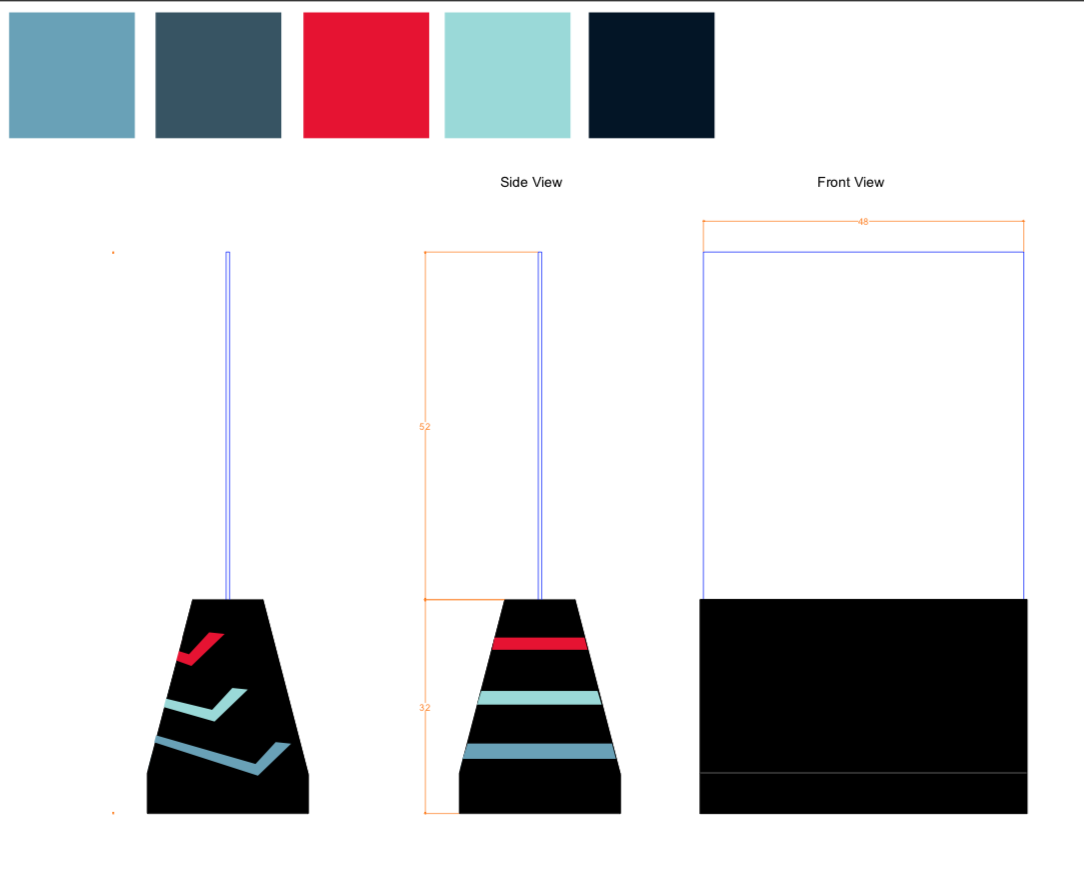

I realized quickly that adjusting the base shape to be more in line with the sides of a hockey rink not only reduced the materials cost dramatically, it added to the visual language and allowed us to reduce our dependence on structurally rigging the sheets to the ceiling grid. That freed us up to utilizing more of the exhibit space and reduce overhead visual clutter. To reduce costs during the lumber price madness during the pandemic, I chose the cheapest plywood and designed my cut-list to maximize each sheet. I made sure each base had a locking access panel to ensure the electronic components could be maintained if necessary during the exhibit. The graphic designer and I worked together to choose the colors, inspired by our local hockey team. I mocked up the painting detail, though the hockey-stick inspired side did not make the final cut. |

|

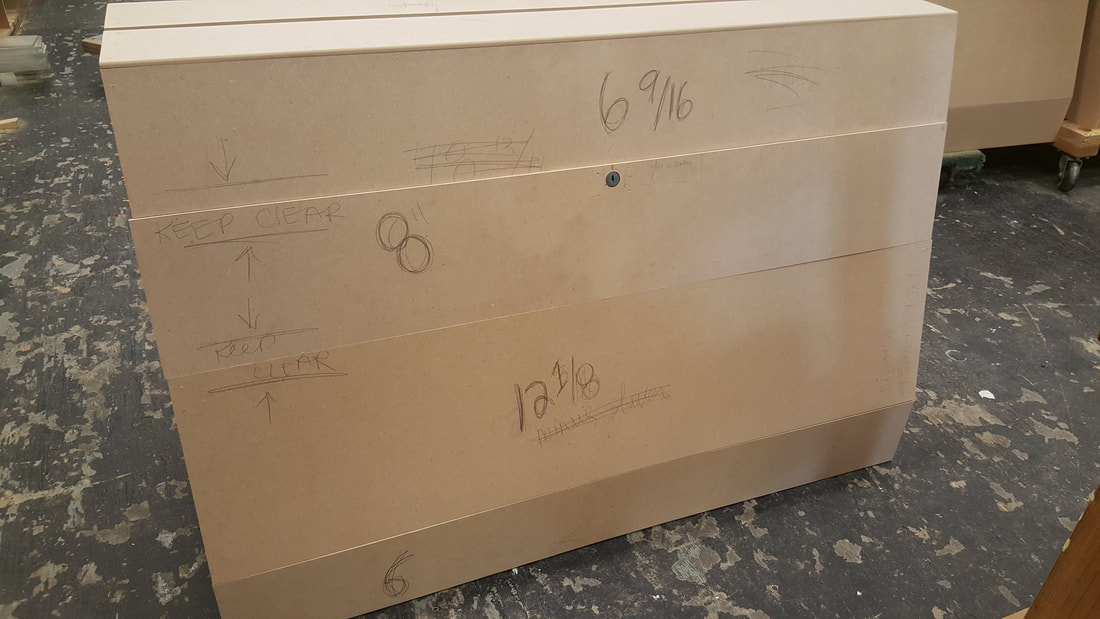

Because this was such a short-term exhibit experience, I was committed to designing in a way that prioritized reusing materials. I only used mechanical fasteners and made sure each base was built identically out of sheet goods that could be disassembled into usable scrap materials. In addition, the acrylic panels only have 2 holes in them, making them incredibly versatile for future exhibits.

You can see the proof-of-concept prototype here, confirming fit test and material specs. I also included an aluminum U-channel to fit the LED strip into. This kept the acrylic panel completely seamless, and maximized the lighting effect by sitting the panel directly onto the lights. The aluminum both distributed the weight of the panel without compromising the tech and prevented light-from leaking into the base instead of the panel itself. |